Third-Party Manufacturing Company for Pharma Products

- IT Department

- Jul 25

- 5 min read

The pharmaceutical industry is one of the fastest-growing sectors worldwide, with a projected market size expected to reach USD 1.5 trillion by 2030. In this competitive environment, third-party manufacturing—also known as contract manufacturing—has emerged as a strategic solution for pharma companies to meet growing market demand without compromising on quality or cost-efficiency. This model has revolutionized the way pharmaceutical businesses operate, offering benefits like scalability, reduced operational costs, and faster go-to-market timelines.

India, known as the "pharmacy of the world", plays a crucial role in the global pharmaceutical supply chain. It not only manufactures affordable medicines but also provides extensive third-party manufacturing services to companies across the globe. Let us explore the concept, advantages, process, and how to choose the right third-party manufacturer for your pharma products.

What is Third-Party Pharma Manufacturing?

Third-party pharmaceutical manufacturing involves outsourcing the production of medicines or supplements to a specialized manufacturing unit. These units are equipped with the latest infrastructure, skilled labor, and certifications such as:

WHO-GMP (World Health Organization – Good Manufacturing Practices)

ISO (International Organization for Standardization)

DCGI (Drug Controller General of India)

FSSAI (Food Safety and Standards Authority of India), for nutraceuticals

In this model, the marketing company (brand owner) focuses on promotion, branding, and sales, while the manufacturer handles production, quality control, and packaging as per the client's specifications.

Why Opt for Third-Party Manufacturing?

1. Cost Efficiency

Setting up a pharmaceutical manufacturing plant requires huge capital investment, machinery, licenses, and expert manpower. Third-party manufacturing eliminates these overhead costs, making it easier for small and mid-sized pharma businesses to enter the market.

2. Focus on Core Competencies

By outsourcing production, companies can concentrate on marketing, distribution, customer relationship management, and expanding their portfolio without worrying about manufacturing logistics.

3. Access to High-Quality Products

Reputed contract manufacturers maintain high production standards and certifications. This ensures that the end products meet both domestic and international quality norms.

4. Flexibility and Scalability

Third-party manufacturers allow businesses to scale up production as per market demand. You can start with small batches and increase volumes when needed, without additional investments.

5. Timely Delivery

Most third-party manufacturers have streamlined supply chains and inventory management systems that ensure timely production and delivery.

Types of Products Manufactured by Third-Party Pharma Companies

Third-party manufacturers usually produce a wide variety of formulations, including:

Tablets

Capsules

Syrups

Injectables

Ointments & Creams

Protein Powders

Nutraceuticals

Ayurvedic & Herbal Products

Drops and Lotions

Softgel Capsules

Dermaceuticals & Cosmetics

Many of these manufacturers also offer custom formulation development, label designing, and packaging solutions.

How the Third-Party Manufacturing Process Works

Step 1: Product Selection and Composition

The client selects the product(s) they want to manufacture, along with desired compositions, dosage forms, and packaging preferences.

Step 2: Documentation and Agreement

Both parties sign a third-party manufacturing agreement. Required documents generally include:

Drug License

GST Number

Company Profile

Copy of Aadhaar and PAN card

Marketing and sales certificate (if available)

Signed quotations

Step 3: Product Approval and Manufacturing

After documentation, the product goes into production. The manufacturer ensures that raw materials meet quality standards and follow cGMP guidelines.

Step 4: Quality Control and Packaging

Before packaging, the product undergoes rigorous quality checks. Once approved, it's packaged as per client instructions, including brand labels, logos, and design.

Step 5: Delivery and Dispatch

The final goods are shipped to the client or distributor. Some manufacturers also help with logistics and warehousing solutions.

Key Features to Look for in a Third-Party Manufacturing Company

Choosing the right partner is crucial. Here are some parameters to evaluate:

1. Certifications and Compliance

Ensure the company holds WHO-GMP, ISO, and other necessary certifications. This validates their adherence to high-quality standards.

2. Manufacturing Capacity

The facility should have the capacity to meet your current demand and accommodate future growth.

3. Range of Products

A manufacturer offering a wide product range gives you more opportunities to expand your portfolio under one roof.

4. Research and Development

If you plan on launching innovative products, choose a manufacturer with a strong R&D team that can support formulation development.

5. Client Testimonials and Market Reputation

Look for companies with a strong track record, transparent dealings, and positive feedback from clients.

6. Value-Added Services

Some manufacturers offer branding assistance, regulatory support, product registration for exports, and even digital marketing tools.

Challenges in Third-Party Pharma Manufacturing

While the model offers numerous advantages, there are also challenges that companies should be aware of:

Dependency on Manufacturer: A delay or quality issue from the manufacturer's side directly affects your brand reputation.

Lack of Customization: Not all manufacturers are open to custom formulation unless you have high order volumes.

Regulatory Risks: It's vital to ensure the partner adheres to all local and international regulations to avoid legal issues.

Current Trends in Third-Party Manufacturing

1. Digital Integration

Many manufacturing companies are adopting ERP software, digital quality control, and automation to enhance efficiency and transparency.

2. Eco-friendly Practices

Sustainable manufacturing and green chemistry are gaining traction as global awareness of environmental issues increases.

3. Global Expansion

Indian manufacturers are increasingly serving clients in Africa, Latin America, Southeast Asia, and Europe, contributing to India’s rising exports.

4. Customization and Branding

Third-party partners are now offering white-label solutions with full customization in packaging, design, and marketing collaterals.

Top States in India with Leading Third-Party Pharma Manufacturers

India is home to several pharma manufacturing hubs. Key states include:

Himachal Pradesh (Baddi)

Punjab (Mohali, Derabassi)

Gujarat (Ahmedabad, Baroda)

Maharashtra (Mumbai, Pune)

Uttarakhand (Haridwar, Dehradun)

Telangana (Hyderabad)

Tamil Nadu (Chennai)

These states offer favorable industrial policies, tax benefits, and robust pharma ecosystems.

Bottom Line: Why Third-Party Manufacturing is the Future

Third-party manufacturing in the pharmaceutical industry is more than just a cost-saving model—it's a strategic partnership that empowers both startups and established businesses to deliver high-quality medicines to the market efficiently. Whether you are launching a PCD pharma franchise, venturing into nutraceuticals, or planning to export pharmaceutical products, choosing the right third-party manufacturing partner can determine your long-term success.

As the healthcare sector continues to grow, demand for reliable and certified third-party manufacturers will increase. Companies that invest in transparency, quality control, and continuous innovation will become leaders in this space.

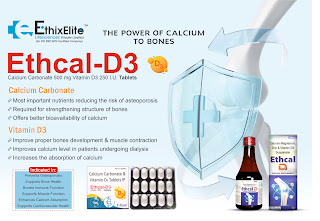

Partner with EthixElite Lifesciences Private Limited

If you are looking for a trustworthy and experienced third-party manufacturing company for pharma products, EthixElite Lifesciences Private Limited is your ideal partner. We are committed to delivering superior quality formulations across a wide therapeutic spectrum, backed by WHO-GMP certified facilities, skilled teams, and exceptional customer service. From ethical marketing companies to government supplies and exports, we serve diverse clients with dedication and precision. Partner with us to scale your brand with confidence and compliance.

Comments